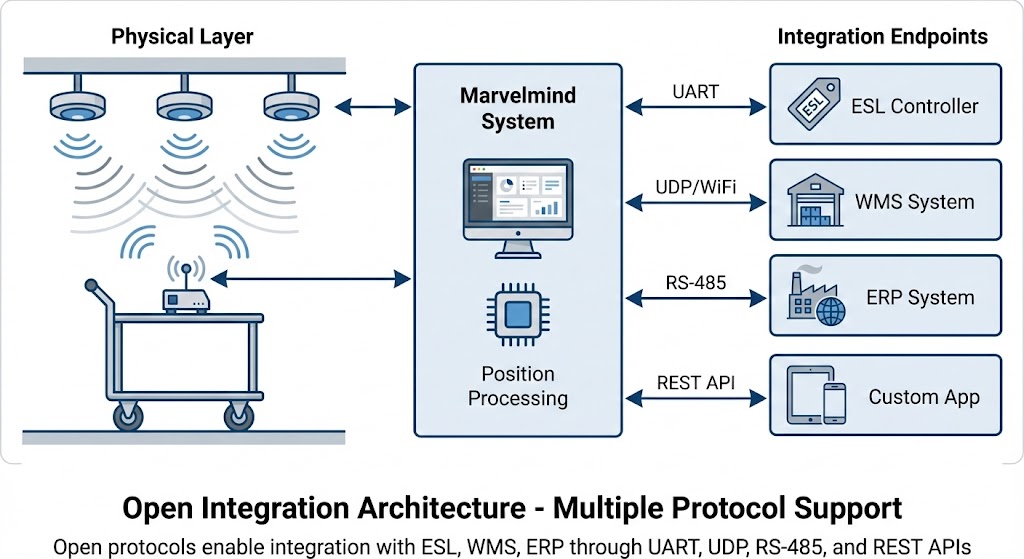

Manufacturing facilities tracking hundreds or thousands of carts need precision. Not 5-meter accuracy. Not "close enough." Centimeter-level precision integrated with electronic shelf labels (ESL) and warehouse management systems (WMS) through open APIs. This is how ultrasound RTLS delivers it.

The Cart Tracking Challenge

A typical manufacturing plant: 325ft x 660ft (99m x 201m), 200,000 sq ft (18,600 sq m). Ceiling heights 12-25 feet (3.7-7.6m). Steel structures, metal racks, overhead cranes, moving forklifts. Track 500 carts with better than 30cm (12 inch) precision. Stream real-time location to ESL systems. Integrate with existing infrastructure.

The requirements stack up fast:

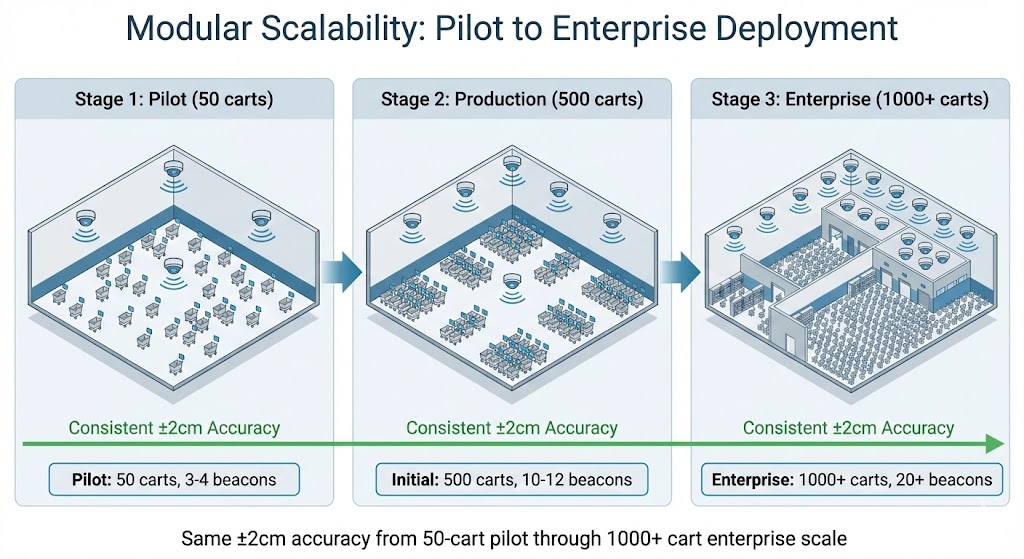

- Scale: 500-1,000+ tracked objects simultaneously

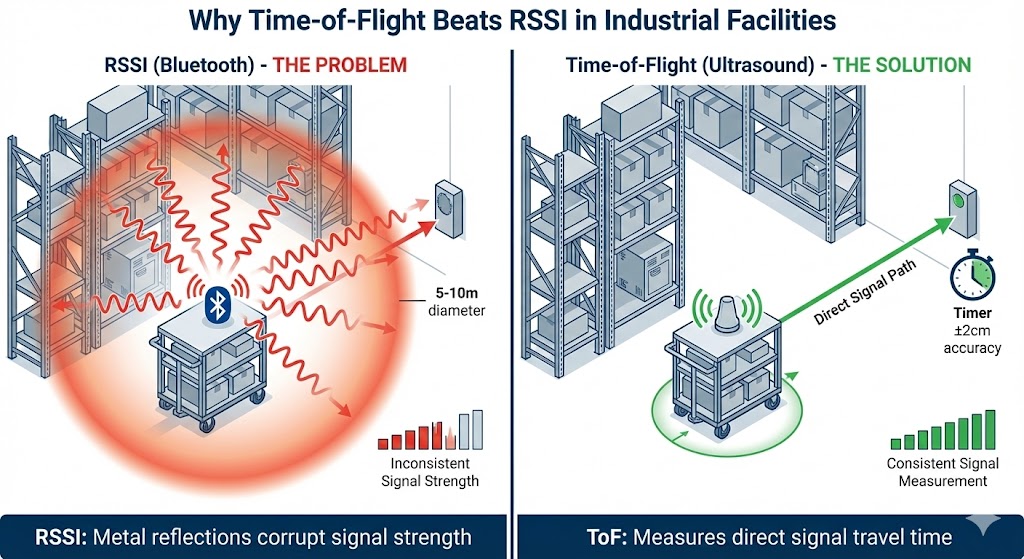

- Environment: Steel structures, RF noise, metal everywhere

- Integration: Open APIs to ESL, WMS, ERP systems

- Reliability: 24/7 operation, minimal maintenance

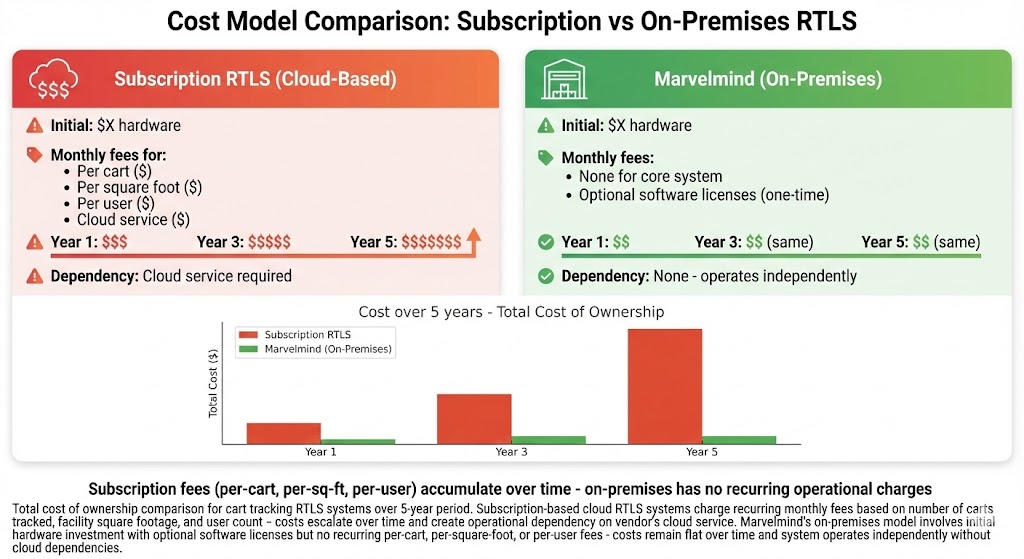

- Cost: Investment must justify efficiency gains