Home » Forklift tracking and monitoring

Forklift tracking and monitoring

Real-time tracking of forklifts for safety and productivity

When you know where your forklifts are in real-time with ±2cm accuracy, you can:

- Allocate tasks based on the current location, thus saving on unnecessary driving

- Increase utilization of your forklifts by knowing how much each forklift has been driven

- Make conclusions when different forklifts covered different distances during a shift and optimize

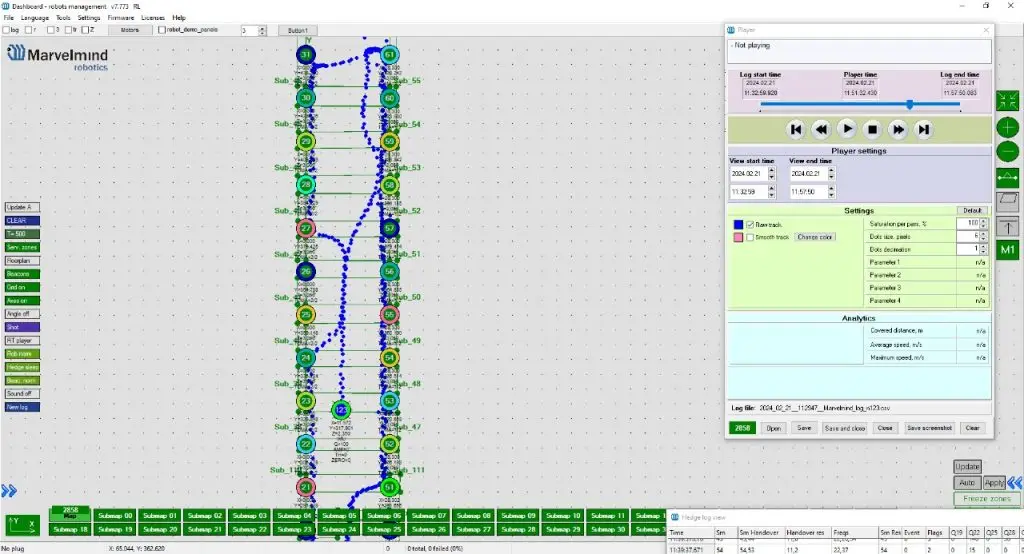

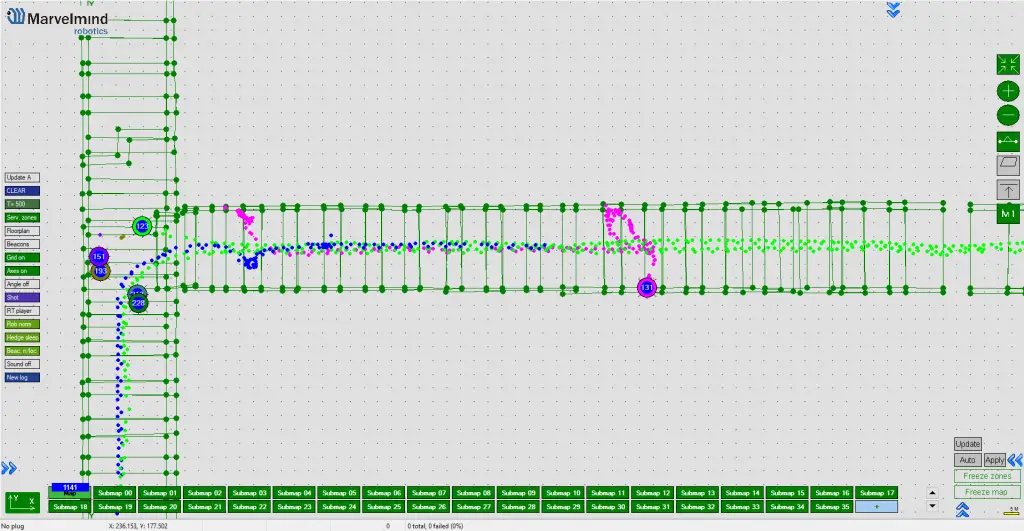

- Improve driving routes by collecting real driving data over time (heatmaps, “spaghetti” maps)

Superior accuracy

Our cutting-edge indoor positioning system, powered by ultrasound technology, offers unparalleled accuracy, surpassing UWB systems by a factor of ten. By harnessing real-time and historical data insights, our system revolutionizes how businesses track and manage their assets.

With our solution, logistics managers gain comprehensive real-time visibility into their fleet. They can precisely locate each asset in real-time and track its historical movements with pinpoint accuracy. This data is then translated into actionable metrics, including distance traveled, runtime versus downtime, loaded versus unloaded time, and task completion duration.

Armed with these invaluable insights, managers can optimize processes, enhance overall efficiency, and maximize the utilization of their fleet through our advanced indoor positioning system.

Tracking forklifts for safety

Forklifts are potentially dangerous for people around, for AGVs and other forklifts, and for goods. Optimization for productivity and efficiency is important but, perhaps, even more important safety.

Having real-time forklift location data gives you:

- Speed of each forklift – preventing over-speeding and reckless driving

- In case of an accident, the location data helps analyzing what exact lead to the accident

- Forklift vs. people

- Forklift vs. AGVs

- Forklifts as mobile geofencing zone

- Basic static geofencing zone

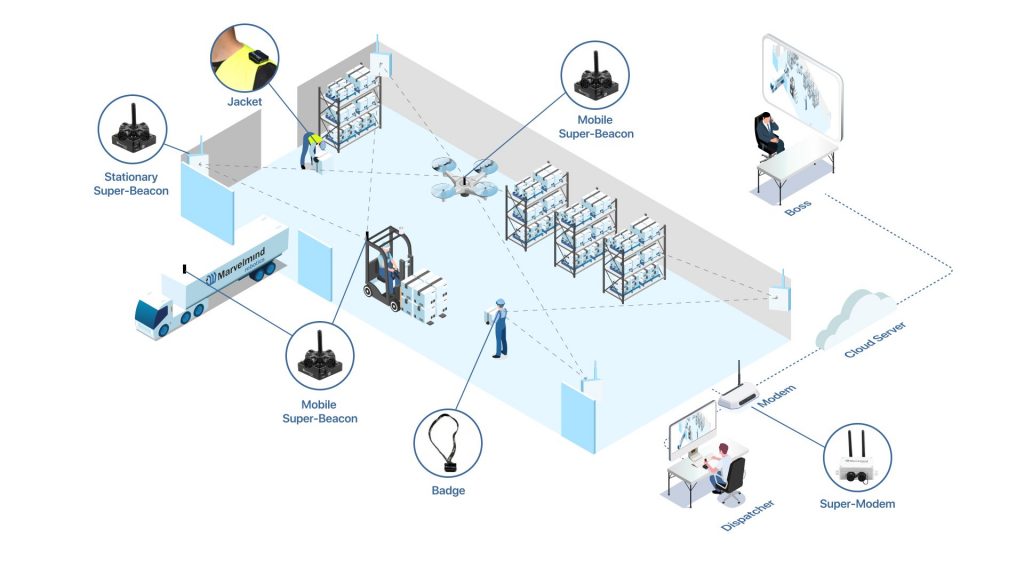

How does real-time forklift tracking system work?

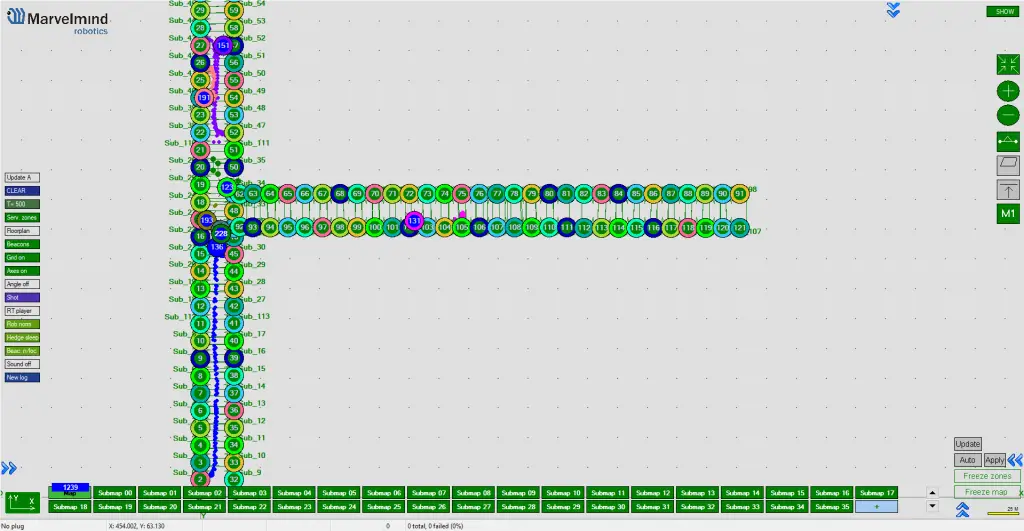

Real-time forklift tracking system doesn’t track a forklift. It tracks a mobile beacon (tag) installed on the forklift.

It is tracking the mobile beacon against stationary beacons (anchors) distributed throughout your premise. Since the stationary beacons’ coordinates are determined during the deployment phase, the system can calculate coordinates of the mobile beacons, and as a result – forklifts – using multilateration.

We don’t run a “server”, that can easily be a single point of failure. In Marvelmind architecture, all calculations are done on site in a distributed manner: some processing is by the stationary beacons; other – but the mobile beacons; overall control of the system and synchronization of elements is done by the modem.

Thus, the key elements of the forklift tracking system are:

- Mobile beacons (tags) installed on your forklift

- Stationary beacons (anchors) that are the distant equivalent of GPS satellites

- Modem – a central controller of the system and a point to collect the tracking data

Different types of mobile beacons

The mobile beacons can be of different types depending on your particular needs and requirements.

Our most recommended solution for tracking forklifts is Industrial-RX with Omni:

Industrial-RX with Omni consists of two major parts:

- Beacon itself with all electronics and connectors in an ingress protected plastic housing

- External Omni-Microphone for the longest coverage

It is very convinient to use Industrial-RX with Omni because you can install Industrial-RX at any place of your convinience and stick out Omni-Microphone – the location sensing part – where it is the best for coverage and accuracy. The Omni-Microphone is small (1x1x1 cm) and installed on a flexible 25-cm tube. It is connected with the main housing by a 1-meter cable.

Power supply for mobile beacons

Forklifts are easy because they are large and have their own electricity. Thus, the best way to supply mobile beacons is to use a DC-DC converter.

On one end it has a 4-meter (can be customized) open wire to connect to the electricity grid of your forklift. And on the other end, it has a 1m wire with a power connector mating for the connector on the Industrial beacons or a Super-Modem.

Power supply for stationary beacons

Power supply options for stationary beacons depend on the types of the beacons used:

- Super-Beacons

- Industrial Super-Beacon

Notice that you don’t need expensive PoE synchronization and wiring for Marvelmind stationary beacons unlike for UWB anchors. PoE wiring may contribute significantly to the total cost of the solution.

Marvelmind stationary beacons require basic +5V DC voltage. All connectivity, data exchange is done wirelessly in a license-free 915/868 MHz band. No need for unnecessary wires.

What data you get from the forklift tracking system

You get precise (±2cm) location data that is about ten times more accurate than that from UWB-based systems.

Along with basic location data among other fields you get:

- IMU data from a 3D accelerometer and 3D gyroscope installed in any Marvelmind mobile beacon

- Raw distance data that helps your own algorithms in case of occlusions

- Geofencing violations

And, of course, all these data in an open protocol that you can download right away.

Additionally to the streaming of data via multiple interfaces such UDP over WiFi, RS485, virtual UART over USB, all the data is stored in CSV files in a open format for post-processing by your apps.

Since we value your GUI, we offer open API that you can control our precise forklift tracking system from your your application with your own GUI.

Key benefits of Marvelmind forklift tracking system

- Accuracy: up to ten times more accurate than UWB

- No need for a cloud: your data doesn’t leave your premise – inherently secure

- We don’t take your data as a hostage in our cloud – we don’t required any cloud or a server

- No need for Ethernet wiring between stationary beacons (anchors) – superior wireless backbone

- Open interfaces – download them and integrate right away

- Transparency in pricing and no hidden costs