Home » Tracking an arm of an excavator and similar cases

Tracking an arm of an excavator and similar cases

How to track machinery parts, other machines, or people against the machine

“I want to track machinery (an arm of an excavator). Is it possible?” – a request from a potential customer.

Surely, it is possible! We even have had similar cases in the past. See more in our presentation. Particularly close are the following slides:

- Construction safety, people and machinery

- Huge AGV, transport and people

Solution

Key requirements

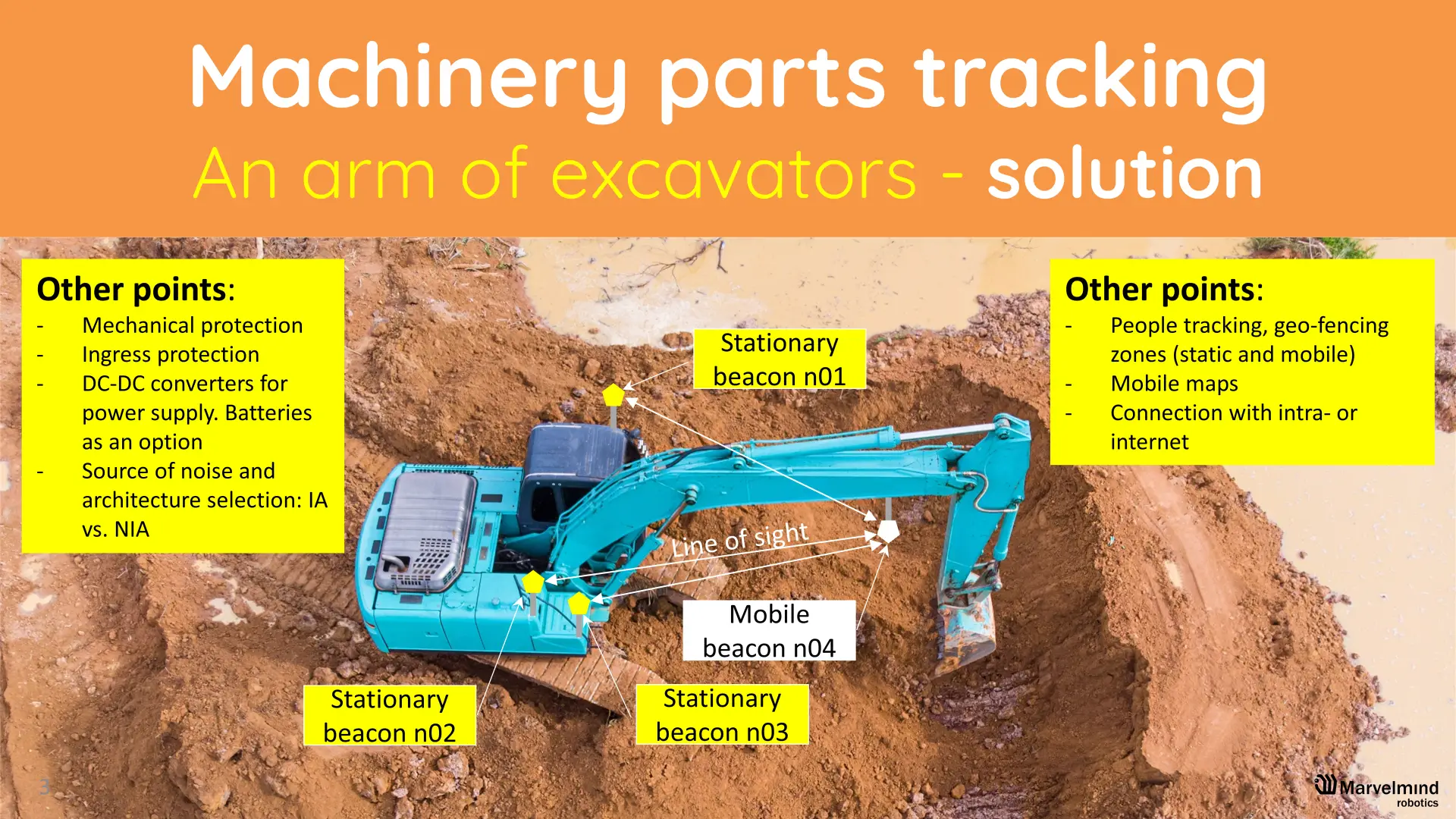

- The line of sight between three or more stationary beacons and the mobile beacon on the arm is a must. It defines everything:

- The architecture: IA vs. NIA – it would be defined mainly by:

Other points to take care

- Mechanical protection of beacons in the harsh environment of the earth-moving machinery

- Ingress protection: rain, dust, snow, ice, sun, wind

- Power supply for stationary and mobile beacons. We recommend DC-DC converters. Battery with IP67 protection is an option as well

There must be a modem in any system – a central controller. It can be placed anywhere within the radio coverage, which is 100-400 meters from the beacons, depending on the used antennas. However, typically, for this setup, the best location for the modem is inside the cabin of the excavator. Since the modem is inside the cabin, it can have minimal ingress protection.

However, the user must take care of where the data about the movement of the arm is ultimately collected. It can be in an onboard computer, for example, which may have a wireless connection to a central system via 4G/5G/satellite.

Or the Super-Modem can stream directly via a connected WiFi/4G/5G/satellite modem via UDP over WiFi to a fixed IP address anywhere in the world.

People and other machines tracking and geo-fencing

The same stationary beacons on the excavator can be used to track other mobile beacons around the excavator, for example, people, other excavators, trucks, or tractors.

The same key requirement – the line of sight between the stationary beacons on the excavator and the mobile beacons on the person – holds. However, it may be even more difficult to meet since the location of the person around the excavator can be less defined; people are more agile and less predictable, i.e. they are more difficult to track then the arm of the excavator that has far less flexibility in movements

The geometry will also impact the tracking accuracy. As compared with the distances to the mobile objects, the base between the stationary beacons is not huge – 2-5 meters. It will impact the accuracy negatively. However, it will still be more than sufficient for typical industrial applications – 10-30 cm.

Other notes

We used the arm of the excavator as an example. However, many other cases are similar, and the solutions are very similar:

- Tracking of a working tool of a drilling machine against the machine or other objects

- Tracking of a hook of an overhead crane against the crane or other objects, for example, loading/unloading trucks

- etc.