Why Ultrasound Outperforms UWB for Industrial Indoor Positioning

In real industrial environments, radio-based systems like UWB hit accuracy and stability limits. Marvelmind’s ultrasound-based RTLS delivers up to ±2 cm precision where UWB often reaches only 15–30 cm.

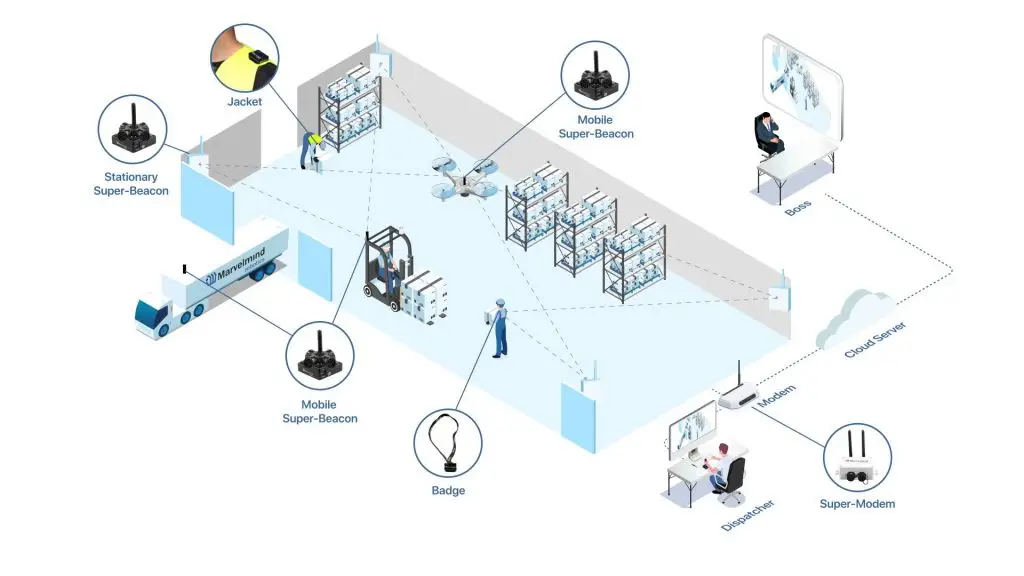

This page gives a practical, engineering-level explanation of why ultrasound is fundamentally more accurate, more stable in RF-noisy environments, and better suited for robots, AGVs, forklifts, drones, and people tracking.

Request Technical Consultation ↗

Talk directly with Marvelmind engineers about your robots, forklifts, or drone project.

1. Core Principle: Time-of-Flight at Sound Speed

Marvelmind uses Time-of-Flight (ToF) measurements of ultrasound between mobile beacons on moving objects and stationary beacons mounted in the environment. The system calculates the position using trilateration in 2D or 3D, similar to GNSS, but indoors.

The key advantage is physics: ultrasound travels at about 340 m/s, while radio-based UWB signals travel at roughly 300,000,000 m/s. The much slower propagation of ultrasound gives enormous timing resolution for distance measurements, making centimeter-level positioning practical with industrial-grade electronics.

2. Speed of Ultrasound vs UWB · Why It Matters

Positioning accuracy in ToF-based systems is directly influenced by how precisely we can measure the delay of the signal. For a given timing resolution of the electronics, a slower signal translates into much finer distance resolution.

3. Practical Accuracy: 2 cm vs 15–30 cm

In industrial deployments, UWB systems typically provide 15–30 cm accuracy, and performance can degrade significantly in metallic and RF-noisy environments.

Marvelmind’s ultrasound-based system routinely delivers:

- 2–5 cm accuracy in typical setups

- ±2 cm accuracy in well-optimized environments

- Best cases down to ±1 cm under controlled conditions

That makes ultrasound-based RTLS a 10× more accurate alternative to UWB for many industrial applications.

Wave speed and timing resolution

| Technology | Signal type | Typical speed |

|---|---|---|

| UWB | Radio | ≈ 300,000,000 m/s |

| Ultrasound | Acoustic | ≈ 340 m/s |

Because ultrasound is almost a million times slower than radio waves, the same timing resolution in the hardware produces orders-of-magnitude better distance resolution.

4. Immunity to RF Noise and Congested Radio Spectrum

Modern factories and warehouses are filled with radio sources: Wi-Fi, BLE, proprietary RF, 4G/5G, and sometimes UWB itself. All of these contribute to RF congestion and interference.

Ultrasound operates in the acoustic domain, not in the crowded RF spectrum. That means:

- Not affected by Wi-Fi, BLE, or cellular interference

- No need to fight against the same noisy RF environment that UWB depends on

- More stable and predictable accuracy over time

This is especially important in heavy industrial environments with large metal structures, cranes, welding equipment, and other RF-noisy machinery.

5. Multipath and Line-of-Hearing vs Line-of-Sight

UWB relies on radio waves that bounce off metal surfaces and create complex multipath patterns. Sophisticated algorithms are required to mitigate those effects, and there are still cases where the positioning error spikes.

Ultrasound interacts with the environment differently. While reflections and blocking still exist, the multipath profile is more manageable and more consistent with geometric expectations.

For best results, Marvelmind requires not only a clear line-of-hearing, but also reasonable distances between mobile and stationary beacons. In most industrial deployments, we recommend keeping the distance within ≈30 m between the mobile beacon and the stationary beacons that serve it.

Longer ranges are possible in ideal conditions (low acoustic noise, optimal orientation, high-performance microphones), while in noisy or obstructed environments the practical distance can be shorter. A deeper engineering-level explanation of coverage, angles, and range limits is given in the guide Line-of-Sight and Line-of-Hearing in Marvelmind RTLS.

Line-of-hearing requirements

Marvelmind requires that a mobile beacon “hears” at least:

- 2 stationary beacons for 2D positioning

- 3 stationary beacons for 3D positioning

In typical industrial layouts, we recommend keeping the distance between the mobile beacon and its serving stationary beacons within ≈30 m. This helps maintain a robust signal level and stable accuracy in real-world noisy environments.

When you need maximum range and robustness, we recommend using the Omni-Microphone IP67 together with the Magnetic Holder. They make it easy to orient microphones optimally toward stationary beacons, which is critical for long-distance operation and installations in harsh conditions.

6. Industrial Benefits Beyond Accuracy

Accuracy alone is not enough. Marvelmind’s ultrasound-based RTLS also provides:

- High update rates and low latency for dynamic robots, AGVs, and drones – see the guide How to Increase Location Update Rate.

- Scalability from small labs to large warehouses and factories thanks to multiple supported architectures (IA, NIA, MF-NIA).

- Integration APIs including ROS, UART / USB / SPI / NMEA, and more – see the full interfaces document Marvelmind Interfaces (PDF).

Together with superior accuracy, this makes ultrasound the most practical technology for demanding industrial positioning tasks.

7. Conclusion: Ultrasound as the Leading Technology for Industrial RTLS

For industrial indoor positioning, ultrasound is not just an alternative to UWB – it is a fundamentally more accurate and more robust technology. Marvelmind leverages this with a mature, field-proven RTLS that has been deployed in warehouses, factories, tunnels, and research labs around the world.

Compared to UWB, Marvelmind’s ultrasound-based system offers:

- Up to 10× better accuracy

- Superior stability in RF-noisy environments

- Predictable performance in metallic and harsh conditions

- Flexible integration with robots, drones, forklifts, and people tracking solutions

Ready to discuss your use case? Request Technical Consultation ↗.