Why the Industry Stays Silent About Ultrasound: The Most Accurate Indoor Positioning Technology for Industrial Applications

Published: January 2026 | Reading time: 12 minutes | Technology Deep Dive | RTLS & IPS Comparison

Everyone in robotics and automation knows about Bluetooth and Ultra-Wideband (UWB). Apple promotes UWB in AirTags. Dozens, if not hundreds, of companies build solutions on ready-made Bluetooth and UWB modules. Yet when it comes to the most accurate indoor positioning technology available today - ultrasound-based systems achieving centimeter-level precision in real industrial environments - the industry falls strangely silent. Why?

The Accuracy No One Talks About

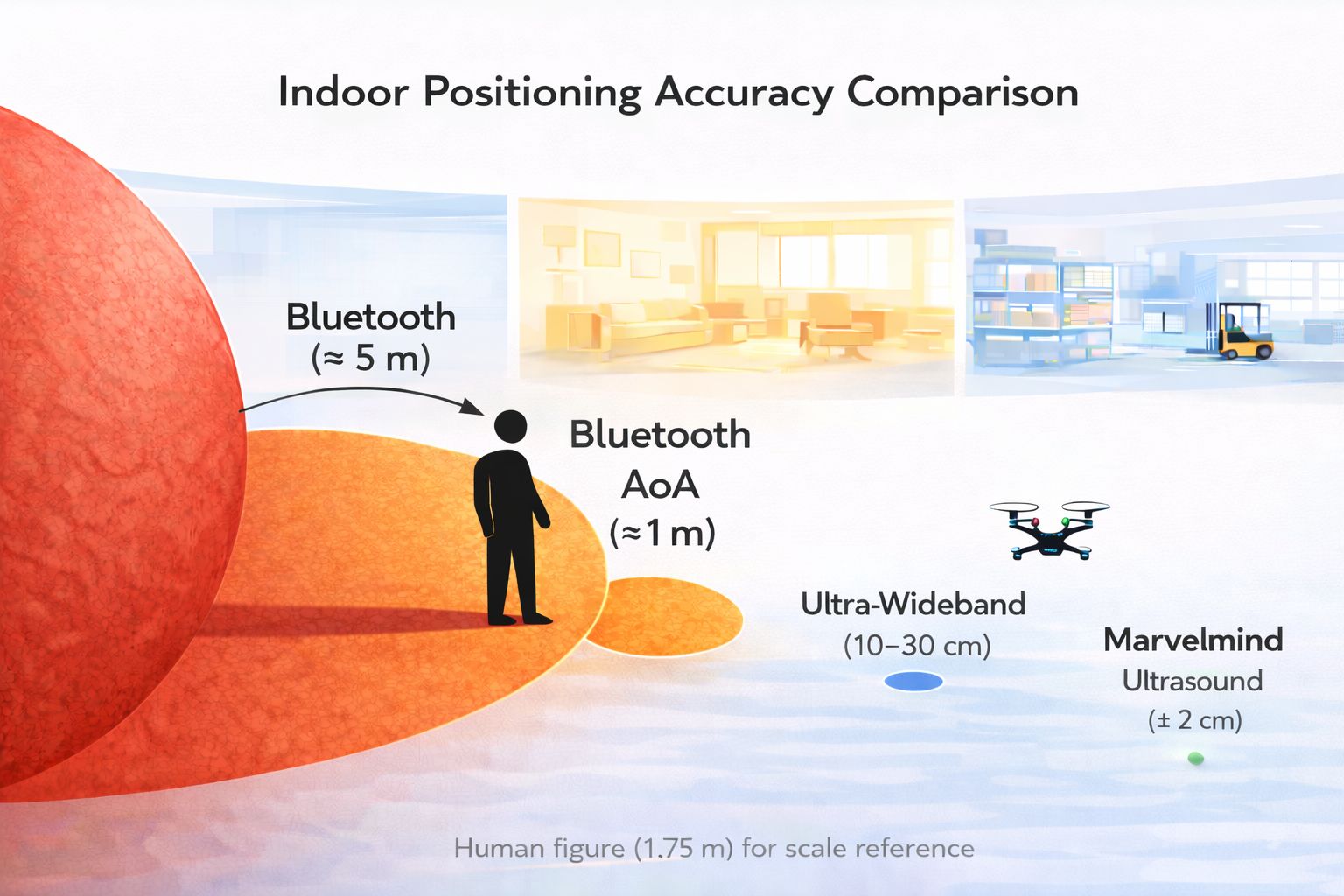

Let's start with a fact that should be making headlines: ultrasound-based indoor positioning systems (IPS) reliably achieve ±2cm accuracy in real industrial environments - and this level of precision is consistent, repeatable, and production-ready. To put this in perspective, UWB-based RTLS solutions typically achieve accuracy in the tens of centimeters range (±10-30cm, or several decimeters) under real-world conditions with metal structures, RF interference, and complex multipath environments that characterize industrial facilities.

±2cm

Reliable positioning accuracy with ultrasound Time-of-Flight technology in industrial environments

This centimeter-level precision is achievable consistently across warehouses, factory floors, and other challenging indoor environments. While sub-cm accuracy is technically possible in controlled conditions with careful beacon placement, the ±2cm specification represents what users can reliably expect in real-world deployments - and this is more than sufficient for the vast majority of industrial robotics, AGV navigation, and automation applications.

About Sub-Centimeter Precision: Can ultrasound achieve millimeter accuracy? Yes, under specific conditions. However, this requires careful attention to beacon placement, mounting rigidity, temperature stability, and measurement protocols. For most industrial applications, the added complexity isn't justified - centimeter-level accuracy already exceeds what AGVs, AMRs, and most automated systems require. If your application genuinely needs submillimeter precision, contact us to discuss the specific requirements and tradeoffs involved.

Marvelmind Robotics has been delivering this centimeter-level accuracy since 2014, operating in factories, warehouses, and research facilities across 50+ countries. Yet despite this proven track record in the most demanding industrial environments, ultrasound remains far less visible than UWB or Bluetooth in industry discussions.

So why isn't everyone using ultrasound? Why does a Google search for "indoor positioning" return pages of UWB and Bluetooth results, with ultrasound barely making an appearance?

The Real Reason: It's Hard. Really Hard.

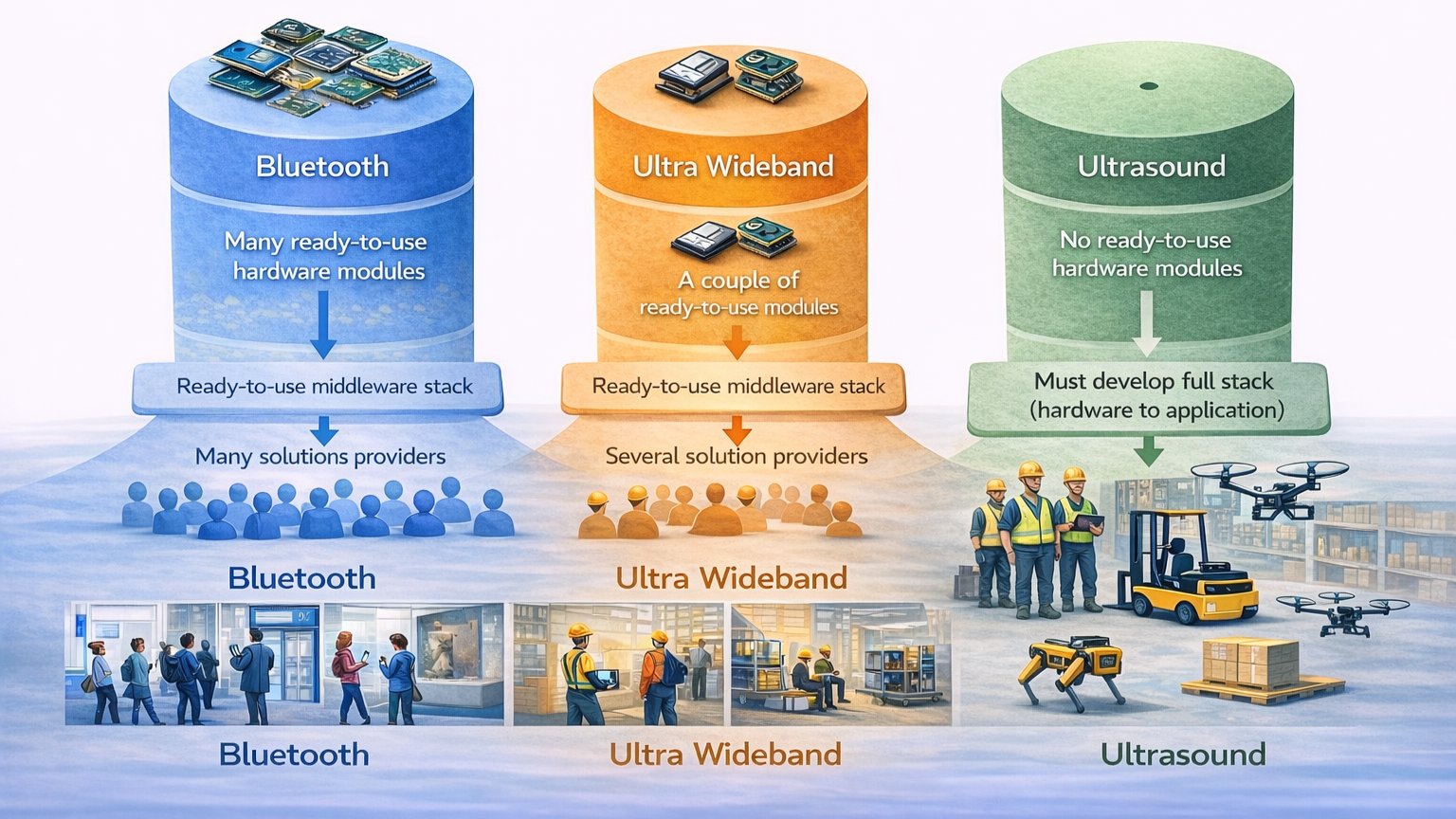

The answer isn't a conspiracy - it's engineering reality. Building an ultrasound-based positioning system from scratch is far more difficult than implementing a UWB or Bluetooth solution.

The Easy Path: Off-the-Shelf Chips

Want to build a Bluetooth-based positioning system? A computer science student can assemble a working prototype on a weekend. Buy ready-made Bluetooth beacons from dozens of manufacturers, write some software, and you're operational. For many applications - asset tracking, basic indoor wayfinding, approximate location services - Bluetooth's 2-5-meter-level accuracy is perfectly adequate, and the rapid development time makes it an attractive choice. With Bluetooth AoA, it is claimed to be around 1 meter.

Again, if the environment is suitable for RSSI-based systems like Bluetooth - not too much metal around, not too many changes in the strength of the radio signal (Bluetooth operates in the 2.4 GHz radio band) due to large moving metal objects, such as forklifts or cranes – Bluetooth can be the right solution. As you can imagine, this is rarely the case in real warehouses or plants. Thus, the right place for Bluetooth- or any RSSI-based systems: museums, exhibitions, and airports – for bringing a person to a shop, a meeting room, or to a gate, not for tracking assets precisely and confidently. If you arrive with a 5-meter error to a gate at an airport, you will find the gate. If you come to a box with 5-meter accuracy, you will spend a lot of time searching for the box.

UWB offers a middle ground with significantly better accuracy. UWB is fundamentally better than Bluetooth for positioning, because it is a time-of-flight (ToF) technology. Chip manufacturers provide ready-to-use silicon with positioning capabilities built in, allowing developers to focus on software and integration. For applications where decimeter-level precision (tens of centimeters) is sufficient, UWB provides a well-supported ecosystem with clear development paths. However, you're inherently dependent on 1-2 chip vendors who supply UWB positioning silicon, and you're limited to whatever capabilities and performance characteristics they've implemented in their chips. It is truly restrictive. All UWB-based solutions from different vendors look as similar to each other in terms of key technical capabilities (range, update rate, power consumption, and the architectures after all) as all laptops using the same Intel or AMD chipsets.

The Entry Barrier Difference:

- Bluetooth positioning: Days to basic prototype, dozens of beacon suppliers, a few meter-level accuracy suitable for many tracking applications where accuracy is not critically important

- UWB positioning: Days to weeks to working system, established chip ecosystem, decimeter-level accuracy (tens of centimeters) for moderate-precision needs. Already very good for industrial applications

- Ultrasound positioning: Months or years of full-stack development required (from hardware to protocols and low-level software and higher-level interfaces and apps), but delivers consistent centimeter-level precision in challenging industrial environments

The Hard Path: Full-Stack Development

Ultrasound positioning has no shortcuts. There are no off-the-shelf ultrasound positioning chips. No plug-and-play modules from major semiconductor companies. To build an ultrasound system, you must design and manufacture:

- Custom hardware: Ultrasonic transducers, special ultrasound-capable microphones, digital signal processing with low power consumption, and reasonable size and cost

- Radio subsystem: High-precision clock synchronization via radio (essential for accurate Time-of-Flight measurements). Ready-to-use protocols are not directly suitable or available

- Low-level firmware: Signal generation, clock synchronization, scheduler

- Communication protocols: Both internal (between beacons and the modem) and external (for data output)

- High-level software: Position calculation, filtering, sensor fusions of different levels, system configuration, and user interface

This is the "Apple approach" - owning the entire stack from hardware to high-level software. It's powerful because it gives complete control and flexibility. But it's also why so few companies attempt it and even less – succeed in it.

Why Physics Favors Ultrasound

Here's the paradox: ultrasound is harder to implement, but easier to make accurate. The physics works in ultrasound's favor.

Speed Matters for Precision

Sound travels at approximately 343 meters per second. Light (and radio waves) travel at ~300,000,000 meters per second. That means ultrasound moves roughly one million times slower than the electromagnetic waves used in UWB.

Why does this matter for practical positioning systems? To achieve ±2cm positioning accuracy, you need to measure time-of-flight with specific precision:

- For ultrasound (343 m/s): Need to measure time to ~60 microseconds precision

- For UWB radio (300,000 km/s): Need to measure time to ~60 picoseconds precision

That's a difference of one million in the timing precision required. While modern electronics can achieve both, the ultrasound measurements are far more robust to the environmental factors that characterize real industrial facilities: temperature variations, metal reflections, RF interference from machinery, and multipath propagation in complex structures. Not to mention, heavy pollution of the GHz bands by Wi-Fi routers and Bluetooth devices.

1,000,000x

Slower signal propagation makes ultrasound inherently more accurate for Time-of-Flight measurements

Better Than LIDAR?

LIDAR systems can achieve impressive accuracy, but they face different challenges:

- Too much light

- Too changing environment

The costs of LIDARs for the dozens of meters range remain high. Weight, power consumption, and size. If it is OK for larger AMRs or AGVs, it is typically way too heavy for drones and unsuitable for people or object tracking.

So, there is clearly a place for LIDARs in industrial environments, but it is a special place for special applications where cost, weight, size, and power consumption are not critical.

The Market Reality: Visibility vs. Capability

Bluetooth and UWB dominate search results and industry conversations, because they have lower entry barriers for developers:

| Factor | Bluetooth | UWB | Ultrasound |

|---|---|---|---|

| Development Complexity | Low - use existing modules | Low to Moderate - chip ecosystem available and modules | High - full-stack development from hardware to software |

| Typical Accuracy | Meters (±1-5m) | Decimeters (±10-30cm) | Centimeters (±2cm) |

| Number of Vendors and Solution Providers | Many dozens to small hundreds | Dozens | Handful globally |

| Best Use Cases | People navigation in a non-industrial environment, wayfinding | Industrial applications with moderate accuracy requirements | High-accuracy industrial applications, indoor mobile robotics, and drones |

| RF Interference Resistance | Susceptible in RF-noisy environments | Susceptible in RF-noisy environments | Very good |

| Acoustic Noise Resistance | Totally immune | Totally immune | Very high for mobile beacons in Non-Inverse Architecture and moderate for stationary beacons. Very high for stationary beacons in Inverse Architecture and moderate for mobile beacons. |

| Air Temperature Fluctuation Resistance | Very high | Very high | High with automatic calibration. Moderate without automatic calibration. |

| Metal Environment Performance | Significant degradation | Multipath challenges | Consistent performance |

| Customization Flexibility | Limited to chip/modules capabilities | Limited to chip/modules capabilities | Full control - highly customizable |

Each technology has its place: Bluetooth excels at low-cost people tracking and navigation in non-industrial environment or even industrial environment when low-accuracy (2-5 meter tracking) is acceptable, UWB provides a good balance for moderate-precision needs, and ultrasound delivers the centimeter-level accuracy essential for demanding industrial robotics and automation applications. The key is choosing the right technology for your accuracy requirements and operating environment.

The Marvelmind Story: Doing It the Hard Way Since 2014

Marvelmind Robotics has been developing ultrasound-based indoor positioning systems since 2012 and came up with a commercial product in 2014, longer than most UWB solutions have existed commercially. The company chose the hard path: building everything from scratch.

Complete Stack Control

Marvelmind's system incorporates two critical technologies working together:

- Ultrasound for Time-of-Flight: Achieving the precise distance measurements needed for reliable centimeter-level accuracy in industrial environments

- Radio for synchronization: Ensuring all beacons maintain precisely synchronized clocks, essential for accurate positioning across large facilities

Neither pillar alone is sufficient - both are equally important. This dual-technology approach exemplifies why ultrasound systems require full-stack development. You can't simply buy ultrasound positioning chips and integrate them; the entire system must be designed as an integrated whole to achieve the robust performance that industrial applications demand.

The Flexibility Advantage

Here's where the investment in full-stack development pays off. When customers need specific features - custom communication protocols, specialized beacon configurations, integration with particular robot platforms - Marvelmind can implement them.

Most application-specific features in Marvelmind's system were requested by customers and subsequently implemented. This flexibility is impossible with chip-dependent systems, where you're limited to whatever the silicon vendor chose to include.

Real-world example: A customer needs precise positioning for forklifts, but they don't want to rely on WiFi for backbone because of previous bad experience. Marvelmind develops and implements a backbone based on RS-485 for the maximum robustness.

When You Need Centimeter-Level Precision

Let's be clear: not every application requires centimeter-level accuracy. For people navigation at a conferences, Bluetooth is perfectly OK. For asset or a forklift tracking in a warehouse UWB suffices. But when your application operates in GNSS-denied environments and demands reliable centimeter-level positioning, ultrasound becomes essential:

- Industrial robotics in GNSS-denied environments: Autonomous mobile robots (AMRs) and AGVs requiring precise docking, navigation in narrow aisles, or coordination between multiple units - in warehouses, factory floors, underground facilities, or GPS-jammed areas

- Precision manufacturing and automation: Automated scanning, inspection, or assembly tasks where position errors cascade into quality issues

- Indoor drones and autonomous vehicles: Navigation in GPS-denied spaces - inside buildings, mines, tunnels - where positioning errors lead to crashes or mission failure

- Research and development: Robotics labs, autonomous vehicle testing, and research requiring ground truth positioning data

- Mining and underground operations: Any subterranean environment where GPS is unavailable and precise positioning is critical for safety and efficiency

- GPS-blocked or jammed facilities: Military installations, sensitive government facilities, or secure industrial sites where GPS signals are intentionally blocked

In these GNSS-denied environments, when operations fail due to insufficient positioning accuracy, the cost - in damaged equipment, production downtime, or safety incidents - vastly exceeds any initial savings from choosing a less precise system.

The Infrastructure Advantage

There's another often-overlooked advantage of Marvelmind's ultrasound system: infrastructure simplicity.

Many UWB systems require network cables to every stationary beacon for time synchronization. This means installation involves both electrical work and network cabling - expensive and time-consuming, especially in existing facilities.

Marvelmind's radio-based synchronization means stationary beacons need only power. One basic power cable instead of two significantly simplifies deployment, especially when covering large areas or installing in hard-to-reach locations like high warehouse ceilings.

Breaking the Silence: What Needs to Change

The industry's silence about ultrasound positioning isn't malicious - it's structural. But it creates a knowledge gap that hurts end users. Engineers designing robotic systems may not even know that consistent centimeter-level indoor positioning is achievable in GNSS-denied environments where GPS is unavailable.

Education Over Marketing

The solution isn't louder marketing - it's better education. Engineers need to understand:

- The fundamental physics advantages of ultrasound for precision positioning

- When the accuracy difference matters for their application

- That complete ultrasound systems are available off-the-shelf despite development complexity

- How ultrasound systems deploy in real industrial environments

"The best technology doesn't always win - the most accessible technology does. Our job is to make ultrasound positioning as accessible as its alternatives, while maintaining the accuracy advantage that makes it valuable."

The Future: Precision in GNSS-Denied Environments

As industrial automation and autonomous systems advance, two trends are converging: increasing accuracy requirements and expanding operations in GNSS-denied environments. Early AGVs operating in open warehouses could tolerate meter-level accuracy. Modern autonomous mobile robots navigating dense factory floors need a decimeter precision. Next-generation applications - collaborative robots working alongside humans, high-speed automated assembly in confined spaces, autonomous operations in underground mines and tunnels - require consistent centimeter-level accuracy.

Simultaneously, more industrial operations are occurring in environments where GPS is unavailable or unreliable: deep inside buildings, underground facilities, GPS-jammed security zones, and RF-noisy industrial environments with heavy metal structures. When these two requirements combine - high precision in GNSS-denied environments -ultrasound positioning becomes not just advantageous, but essential.

The question for industrial automation isn't whether to adopt high-precision positioning in GNSS-denied environments, but whether to build such systems from scratch (repeating years of development) or deploy proven solutions from the few vendors who've already solved these challenges at scale.

Experience Centimeter-Level Precision in GNSS-Denied Environments

See how Marvelmind's ultrasound-based system delivers reliable ±2cm accuracy in challenging industrial environments where GPS is unavailable: warehouses, factory floors, underground facilities, and GPS-blocked areas. Request a technical consultation for your specific application.

Explore Marvelmind Systems →And One More Thing: The Range Reality

If you've researched ultrasound positioning online, you may have encountered claims that ultrasound systems have limited range - as low as 5-10 meters. Some sources list echo interference as a fundamental limitation. Others claim identification isn't possible with ultrasound beacons.

These aren't theoretical limitations of the technology. They're practical limitations of other implementations. Marvelmind's system, developed since 2014 with deep focus on full-stack ultrasound positioning, doesn't have these constraints. While we're less known at the moment, this series of articles aims to share the reality: properly implemented ultrasound indoor positioning systems (IPS) achieve far more than commonly published specifications suggest.

What the Industry Gets Wrong

Let's address the common misconceptions directly:

Myth #1: Ultrasound range is limited to 5-10 meters

Reality: Marvelmind's system achieves 30-50 meter range in 2D and 3D positioning - and up to 100-120 meters in 1D tracking applications using directional horns. We recommend up to 30 meters for guaranteed tracking quality in real-world noisy environments, but the physics and implementation support significantly longer distances.

Why do some sources claim 5-10 meters? Because that's what they achieved with their implementation. Range limitations in other RTLS (Real-Time Location System) solutions typically stem from insufficient transmitting power, non-customized transducers, not properly selected special ultrasound microphones, sub-optimal signal processing and algorithms - all the elements that constitute the know-how of building a proper ultrasound-based indoor navigation system (INS).

Myth #2: Echo/multipath reflections are a fundamental problem

Reality: In properly designed Time-of-Flight systems with line-of-sight conditions, the direct signal always arrives first - echoes arrive later and can be reliably distinguished from the direct path. This is the same challenge UWB systems face with radio multipath, and the same principle applies: proper signal processing handles it.

Line-of-sight is a fundamental requirement for any high-precision indoor positioning system - regardless of technology. For visual systems, line-of-sight means you can see the target. For radio (UWB), it means radio transparency. For ultrasound, it means the direct acoustic path exists without obstruction. When line-of-sight is maintained, echo presents no issues for Marvelmind's RTLS in real-world deployments.

If echo is causing problems in an ultrasound IPS, it indicates insufficient understanding of ToF implementation fundamentals or operation without proper line-of-sight conditions.

Myth #3: Ultrasound beacons can't be individually identified

Reality: Marvelmind's system is ultrasound plus radio - a dual-technology approach. Every mobile beacon has a unique identifier transmitted via the radio subsystem, exactly like UWB and Bluetooth systems. Individual beacon identification is as straightforward as with any RF-based positioning technology.

Myth #4: Acoustic noise is an insurmountable problem

Reality: Just as UWB systems are susceptible to RF interference in environments with heavy Wi-Fi and Bluetooth usage, ultrasound systems can be affected by acoustic noise. This is why Marvelmind offers both Non-Inverse and Inverse architectures - each optimized for different acoustic environments. Acoustic noise is a factor to consider during system design, not a fundamental limitation.

Coverage Without Limits

Another common misconception: coverage area limitations. Some sources suggest ultrasound systems can only cover small areas.

The 30-50 meter range applies to each beacon-to-beacon distance, not total coverage area. Using submaps, maps, and supermaps, a Marvelmind system can contain hundreds or thousands of beacons, covering facilities of any size - warehouses, factory floors, mining operations spanning hundreds of meters or more. There are no inherent limitations on total coverage area.

Why This Misinformation Persists

We believe many of these limitations in published comparisons reflect what individual teams were able to achieve, not what the technology fundamentally supports. Ultrasound positioning requires full-stack development - if any component is suboptimal (transducer design, signal processing, synchronization protocols, filtering algorithms), performance suffers.

Rather than acknowledge implementation challenges, it's easier to claim the technology itself is limited.

Seeing Is Believing

Rather than making absolute claims, we encourage you to review the evidence. We have extensive video documentation on YouTube and real-world deployments demonstrating:

- Tracking at 30-40 meters in 2D/3D environments

- Tracking at 100-120 meters in 1D configurations (aisles, crane tracking)

- Robust operation in acoustically noisy industrial environments

- Individual beacon identification in systems with hundreds of mobile beacons

- Reliable performance when line-of-sight conditions are maintained

If you have doubts about ultrasound RTLS capabilities based on what you've read elsewhere, we encourage you to contact us directly. We'll provide technical documentation, deployment videos, and reference installations that demonstrate the actual performance characteristics of Marvelmind's indoor positioning system.

Every technology has limitations - we're not claiming otherwise. What we are saying is that much of the information easily found online about ultrasound-based IPS simply doesn't reflect the reality of what properly implemented systems achieve. The proof is in the videos anyone can verify on YouTube and in the hundreds of production deployments worldwide.

The technology works. It works at ranges that surprise many engineers. It works in challenging industrial environments. The question isn't whether ultrasound can achieve these results - Marvelmind systems prove it daily. The question is whether other implementations have invested the engineering effort required to realize the technology's full potential.

Conclusion: The First Choice for Precision in GNSS-Denied Environments

The industry's relative silence about ultrasound positioning reflects development complexity, not technological limitations. While Bluetooth serves people tracking needs and UWB provides moderate precision for many applications, ultrasound-based RTLS and indoor navigation systems (INS) deliver consistent centimeter-level accuracy in the most challenging industrial environments where GPS is unavailable or unreliable.

Since 2014, Marvelmind has refined ultrasound positioning technology to deliver ±2cm accuracy in a deployable, production-ready indoor positioning system (IPS). The technology proves itself daily in warehouses with metal racking, factory floors with RF noise, underground mines, GPS-jammed facilities, and other GNSS-denied environments where precise autonomous operation is critical.

When your application demands the most accurate RTLS for industrial robotics, when you're operating in GNSS-denied environments - indoors, underground, or GPS-blocked areas - when centimeter-level precision is essential for safety and efficiency, ultrasound positioning isn't just an option. It's the proven choice for the world's most demanding autonomous operations.

About Marvelmind Robotics: Marvelmind provides the most precise (±2cm) indoor positioning system (IPS) and real-time location system (RTLS) for autonomous robots, drones, AGVs, and industrial automation operating in GNSS-denied environments. The ultrasound-based indoor navigation system (INS) delivers reliable centimeter-level accuracy in challenging conditions: warehouses, factory floors, mines, tunnels, GPS-blocked areas, and any indoor environment where GPS is unavailable. Learn more at marvelmind.com