Indoor positioning accuracy beyond BLE and Bluetooth AoA: is ±2cm possible?

BLE and Bluetooth AoA are widely used and proven indoor positioning technologies – easy to deploy, cost-effective, and great for room-level navigation. Manufacturers report 1–5m accuracy, sometimes up to 1m under ideal conditions with Bluetooth AoA.

If your application requires significantly higher precision – robots, autonomous forklifts, AGVs, or precise personnel tracking – Marvelmind’s ultrasound-based indoor GPS achieves ±2cm accuracy, using time-of-flight instead of signal strength. That’s up to 100× more precise than BLE, and it maintains this accuracy regardless of metal structures or moving machinery nearby.

What is BLE?

You don’t have an additional mobile beacon to track your location. Typically, your mobile phone or tablet, or similar gadget, already has a BLE module, and by adding a particular SW/app to your device, you can track your mobile phone/tablet/gadget

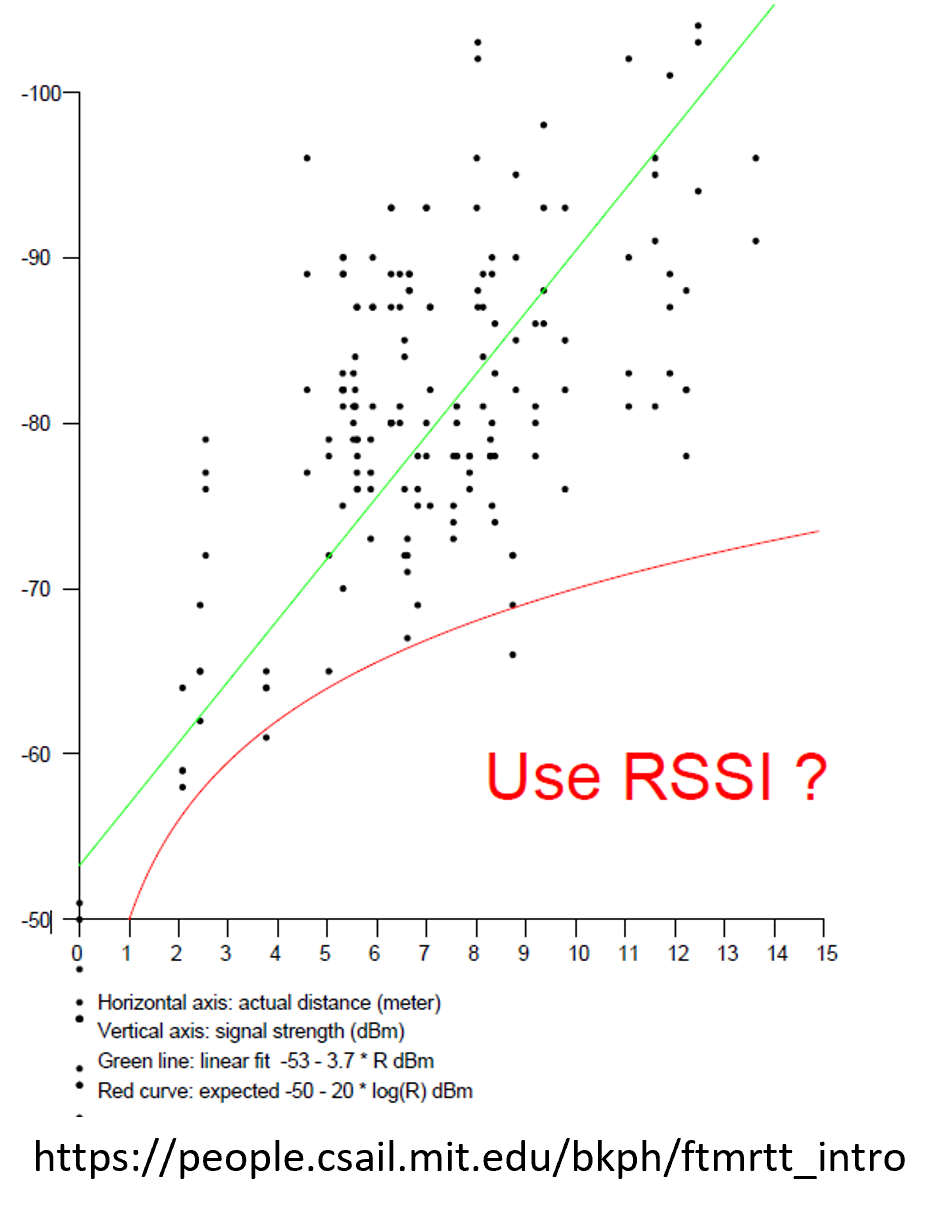

Weakest:RSSI-based systems, including BLE, estimate distance from signal strength — which works well in open, unobstructed spaces. In environments with dense metal shelving,moving forklifts, or concrete structures, signal reflections (multipath) can affect positioning accuracy. This is not a flaw of BLE specifically — it is a fundamental characteristic of all RSSI-based technologies, including Wi-Fi.

Time-of-flight systems — UWB and Marvelmind ultrasound — measure the travel time of a signal rather than its strength, which makes their accuracy independent of the surrounding environment.BLE can be more complex and more advanced, and support Angle of Arrival (AoA) and Angle of Departure (AoD)

- A combination of imprecise RSSI + angles => up to 3 times better accuracy of positioning

- Multiple antennas => larger size, considerable cost, limitations of applicability

Study more about different indoor positioning technologies first

When to use BLE for indoor positioning system

When you need room-level accuracy and already have a mobile device with BLE onboard, the BLE RTLS is a good choice. This is an ideal case. Typical applications:

- To find a gate at the airport

- To find a masterpiece in a museum

- To find a shop in a shopping mall

You place BLE beacons every 10-30m inside your premises. The beacons are small and can be easily camouflaged. For example, they emit Bluetooth signals once per second, and with this location update rate, they can run on an internal battery for one year or so. After one year, you change the battery on all of them.

You use mobile phones as your mobile trackers don’t need any changes or add-ons. They run an application that communicates with stationary beacons and calculates their position based on the radio signal strength of particular stationary BLE beacons and their known position. Everything works very well, albeit not too precisely – 2-5m typically, which is OK for many applications (see examples above) but not for most industrial applications.

Why exactly BLE is not good for industrial applications

Insufficient accuracy

A typical requirement for people tracking in industrial applications is better than 1m. Often – better than 0.5m. BLE is not capable in the practice of providing such accuracy, or you need to place the BLE stationary beacons very densely – every 2-5m.

Metal around

When we receive requirements about an indoor positioning system, potential customers often highlight that they have metal around. We immediately know they have probably burnt their feet with RSSI-based systems, typically BLE. Why? How do we know?

As previously discussed, RSSI-based indoor positioning systems utilize the radio signal strength from a stationary beacon to the mobile beacon to estimate the distance. Yes, the farther your mobile beacon (phone) is from your stationary BLE beacon, the weaker the signal shall be. In practice, however, the RSSI fluctuates so drastically that the same RSSI may be measured on 2m and 10m. What distance is then?!

Everything is more or less OK when you have nice and empty spaces of airports or shopping malls full of radio-transparent glass or thin walls. However, when you need to navigate a crowded warehouse filled with metal shelves, pallets, forklifts, or other heavy machinery, the RSSI picture changes so drastically that BLE-based tracking fails to work with acceptable accuracy. Like really doesn’t work. You can be on this aisle or one or another. And what is the point of the system if you can not find what you want?

RSSI picture changes all the time

There is not only metal in the industrial environment, but also moving metal. Imagine you are not moving, but a forklift is moving 5m from you. However, your location, as measured by the BLE-based system, jumps. Why? This occurs due to multipath fading. Thus, a system calibration you did one hour ago may immediately become invalid.

Of course, intelligent algorithms try to recover somehow and recalibrate the system. But in the end, it does not work well in the real industrial environment. RSSI-based systems are not designed for such environments.

You have to have dedicated mobile beacons in industrial environment

Life looks cool when you track mobile phones: download an app, and you are tracked. But what do you need to track, not a phone, but something else? Helmet? Crane? Palette? Forklift? – You need to install a mobile beacon on it—just another device. Well, for precise indoor positioning systems, you always need a mobile beacon, but they are accurate, at least. With this situation, you have both (1) poor accuracy and (2) an additional mobile beacon with all the difficulties of charging, additional costs, etc. One of the most decisive advantages – not requiring a separate mobile beacon for tracking – evaporates from BLE systems in an industrial environment.

What is better than BLE for industrial applications?

There are two major technologies recommended for industrial indoor positioning systems:

- UWB (ultra-waveband radio)

- Ultrasound (Marvelmind Indoor “GPS”)

As discussed in the Review and comparison of indoor positioning technologies and methods focusing on industrial applications, both technologies rely on the time of flight, not on RSSI. That is the key advantage because it does not matter what is around: metal, concrete, wood, or nothing at all. UWB – time of flight of the radio wave. Ultrasound – time of flight of ultrasound. Since the speed of sound is approximately a million times slower than that of radio waves, ultrasound-based solutions are inherently far more accurate than UWB.

Therefore, the key practical advantages:

- If you need the highest accuracy available (at least ten times better than UWB), choose Marvelmind Indoor “GPS”

- If you have a wooden/glass radio, transparent walls, or your environment is very acoustically noisy, then choose UWB

- If you need a lower-cost solution, select Indoor Marvelmind “GPS”

Of course, like for any precise indoor positioning system, line of sight is a must, but the definitions of what exactly “line of sight” is differ:

- Radio transparent walls (thin glass, wood, etc.) give a line of sight for UWB, but not a line of sight for ultrasound

- At the same time, typical “breathing” cloth is transparent for ultrasound as well, even if the mobile beacon is not visible, i.e., out of the line of sight – for light, not for ultrasound

What about optical tracking or LIDARs?

Indoor optical positioning systems continue to improve when used in conjunction with drones or robots. They are already excellent at maintaining a very steady position, but can lose it when the object is mobile. The devil is in the details:

- Optical systems work well for monitoring, but less so for positioning, and even worse for navigation

- Distnguish between inside-out (they can work well but require substantial processing power) and outside-in systems (they are stationary and have difficulties with distinguishing similarly dressed people, for example)

- Ultrasound stationary beacons can run on a battery, though a fixed power supply is recommended. The power supply, in this case, is typically a basic electricity grid (~110/220V) or a USB port or a +12-36V power source, whichever is more accessible. UWB normally requires a fixed power supply for stationary beacons (anchors), which also need Ethernet for data exchange and synchronization. However, stationary cameras (outside-in systems) require power and a high-speed connectivity backbone, either Ethernet or wireless. Also, servers process massive data streams. It is simply costly and cumbersome to provide all that connectivity

- Line of sight is a stronger requirement for optical systems than for ultrasound and UWB

- Accuracy depends on the distance, unlike in the time-of-flight systems. Higher-resolution cameras become even more expensive and have other drawbacks

- A typical industrial environment is poorly lit – either too dark or too bright or both – with too high a dynamic range

- In many cases, dust, fog, temperature change, and condensation

LIDARs are suitable for well-structured industrial environments, but:

- Can struggle in more messy and changing environments

- Generally speaking, more expensive and more tuned for obstacle detection rather than positioning

- LIDARs are not suitable for people tracking at all and typically too expensive for forklift tracking