Precise tracking for cranes and hooks

To improve safety and productivity, it is often vital to know the position of the crane hook with high accuracy. Moreover, the position of the hook and the load on it must be known not only in XYZ coordinates relative to the walls but, even more importantly, relative to other mobile objects. Also, it is often important to know the XYZ coordinates and the hook swing and twist angle.

So, how do you track the position of a hook of overhead cranes with high accuracy in a typical industrial environment where RTK GPS is unavailable because GPS is not available at all? Recommended solution – Marvelmind Precise Indoor “GPS”.

Key features of the system:

- Precise tracking with ±2cm accuracy

- Real-time three-dimensional (XYZ) positioning with roll, pitch, and yaw data, with a typical 8Hz location update rate and 150ms data latency

- Geofencing or “no-fly” zones. Automatic alarms are triggered when records are violated in the system

- All calculations are done on the spot. No need for a cloud. However, if you wish, your hook location can be streamed in real-time anywhere

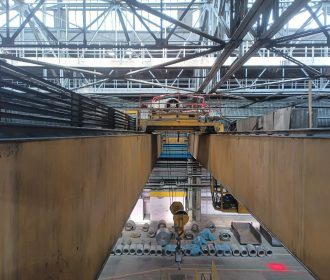

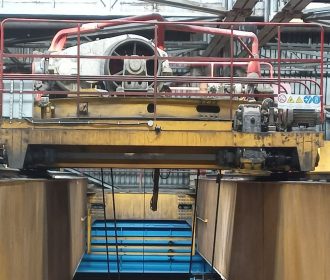

Precise cranes and cranes' carts tracking in XY

Request:

- To precisely track 8 bridge cranes and the cranes’ carts in XY

- Cranes are 36m wide, and they travel up to 480m on rails

- Three separate lanes of cranes (480m – 4 bridge cranes, 280m – 2 bridge cranes, 180m – 2 bridge cranes)

Solution:

- 28 x Industrial-RX with Horn

- 16 x Industrial Super-Beacons

- 3 x Super-Modem

- Fixed external power supply +12V

- MF NIA

- Split X-axis and Y-axis tracking

- Distances covered by Horns – up to 55m. See more about ultrasound frequency selection

Key elements of precise indoor positioning system for crane hooks

High-precision tracking of a crane hook does not fundamentally differ from tracking any other object in 3D but has its practical implementation features.

As with any high-precision tracking system, the system should include the following:

- Stationary beacons

- Mobile beacon or beacons

- A modem as a central controller of the system

Learn a bit more about basics of the architectures.

Then, of course, it is essential to clearly understand what is positioned/tracked/localized against what:

- Hook against the walls?

- Hook against the crane cabin?

- Hook against the vehicle with the load?

There are two primary options:

- Hook and crane are tracked against the walls/ceiling directly

- Hook is tracked against the cabin of the crane. The cabin is tracked against the crane. The crane is tracked against the walls

Each approach has its pros and cons. The choice mainly depends on the requirements and limitations of your particular project.

For more insights into different options for tracking the crane hook, watch the video below.

Since there are always special cases and special wishes, just send us an email to info@marvelmind.com and let’s have a Zoom session and discuss your specific requirements in detail. Since we have full control over the system (architecture, hardware, firmware, higher-level software), we can tune nearly anything to any need.

Most important requirement for precise indoor positioning system

Remember the essential requirement for a precise tracking system: to track, the mobile beacon must have a direct line of sight (or hearing) to two or more stationary beacons within 30 meters for 2D or three or more for 3D.

More about the main requirement: Line of sight is a must for precise indoor positioning systems.

Specifics of high-precision crane hook positioning

3D tracking

Tracking of a crane hook requires 3D tracking, obviously.

3D tracking (XYZ) is just a subset of multilateration. It is not fundamentally more complex than 2D (XY) tracking. At any given time, the mobile beacon on the hook must have a direct line of sight to 3 or more stationary beacons within 30 meters for 3D, or to 2 or more stationary beacons for 2D.

3D positioning is not drastically different from 2D positioning. But it does have implications. For example:

- With four stationary beacons – a pair on the left wall and a pair on the right wall – it is possible to achieve 2N redundancy. This makes the system very resilient against obstructions of stationary beacons. One would need to block 50% of the beacons to make the system incapable of localizing the mobile beacon

- At the same time, to achieve 2N redundancy for 3D, a minimum of six stationary beacons are required. But with the blocking of unlucky two beacons, which is 1/3, not 1/2 for 2D, the 3D system won’t have 3D tracking anymore, i.e., the 3D tracking system is more fragile, and more redundancy is required to achieve a comparable level of resilience against the obstructions or any other interference

- More stationary beacons are not just the cost of the hardware and software. It involves more installation, more permits, more powering, and more limitations due to frequency allocation, among other things. It is a chain of complexities that is better to be avoided than tackled

- Crane in 1D against the wall

- Since the overhead crane has a known structure, it is possible to track its cabin against the crane itself precisely

- Install stationary beacons on the cabin (they will be stationary beacons for the hook, but mobile for the external world) and track the hook against the cabin in 1D or 3D plus pitch, roll, and yaw because it is easier to do it against the cabin than to do it against the walls, because of potential obstructions

Crane hooks are huge. More than one mobile beacons is recommended

Since the line of sight between stationary and mobile beacons is the most critical requirement, the size of the hook becomes an issue.

The hook is typically so huge that it creates shadows and is impossible to track in 3D (XYZ) easily. One has to install too many stationary beacons to track a mobile beacon on the hook.

Instead, combining with installing additional mobile beacons on the hook is recommended. It saves the costs of the system, increases the resilience against obstructions – both near the stationary beacons and near the mobile beacons – and improves overall performance because distances between the stationary beacons are known. Suppose more than one mobile beacon is visible to the stationary beacon. In that case, it is possible to calculate the position of the hook with higher accuracy based on the location of more than one mobile beacon.

Crane hooks are dangerous by nature

Yes, forklifts and AGVs can be dangerous, but huge overhead loads are even more hazardous, particularly when handling radioactive materials or high-cost, bulky products.

Therefore, a particular focus on the resiliency and accuracy of the system is essential.

Plants are huge. Larger precise indoor positioning systems required

An example overhead crane system:

- Overall length – 470m

- Each hook weighs more than 2 tons and is capable of lifting several dozen tons

- Height of the building: 30-40m

- Distances between walls – 70m

Such a monstrous system requires a larger indoor positioning system. It may have significantly fewer beacons, but the distances between them may be considerably larger. In turn, it would need special solutions to increase the range, such as Marvelmind Horn to increase ultrasound range and directional antennas to increase radio range.