What Is RTLS? Real-Time Location System — Definition, Technologies, and Applications

The acronym RTLS stands for Real-Time Location System. RTLS is often referred to as RTLS systems, which is incorrect, but convenient.

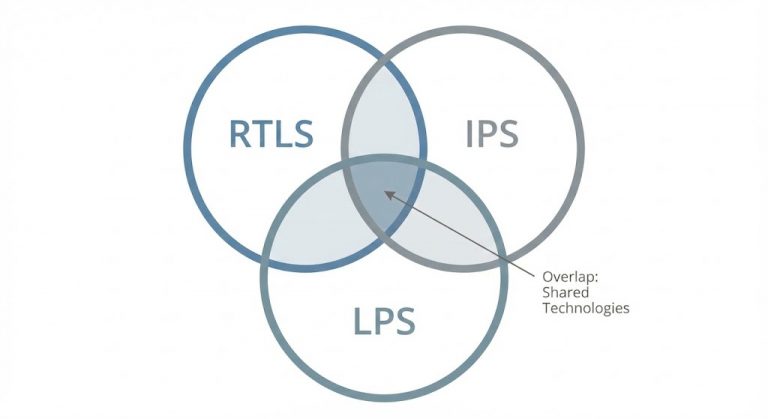

RTLS vs IPS vs LPS — What Is the Difference?

RTLS is not limited to indoor environments – but in practice, it almost always refers to indoor positioning systems (IPS) or local positioning systems (LPS). That is because outdoors, GPS and RTK GPS already solve the positioning problem for most applications.

When a GPS signal is available and the sky is open, RTK GPS delivers centimeter-level accuracy and is the default choice for outdoor navigation. RTLS becomes the solution when GPS fails — inside buildings, underground, in tunnels, or in facilities where satellite signals are blocked or deliberately jammed.

Therefore, in practice, RTLS = IPS. If you are looking for a real-time location system, you are almost certainly looking for an indoor positioning system.

Why GPS and GNSS Are Not Considered RTLS

Although not limited to indoor positioning systems (IPS), when discussing RTLS, it usually refers to the various types of indoor positioning systems. Sometimes, they are also referred to as local positioning systems (LPS).

GPS is also a type of RTLS system, but GPS is part of the global navigation satellite systems (GNSS), which also include GLONASS, Galileo, and BeiDou.

Why RFID Is Not a True RTLS — And What It Is Instead

RFID stands for Radio Frequency Identification. Just as BLE, WiFi, LoRa, and ZigBee, which are not designed for positioning systems, can still be used for this localization and navigation, and RFID is not a positioning system but, with a particular stretch, can still be used for these purposes.

Of course, the stretch is serious. You don’t know the location of your mobile object, your mobile beacon, or your tag. You know whether the tag was registered within 0.1-1m from an RFID reader. Typically, 0.05-0.1m and only for some special readers, within 1m. But you don’t even know the distance. You only know yes or no. You don’t have the XYZ coordinates of your mobile beacon. You have only XYZ of your RFID reader.

Industrial Applications of RTLS — Warehouses, Manufacturing, Mining

Since we focus on industrial applications, we do not cover other areas in the article, such as retail, healthcare, hospitality, agriculture, and security. RTLSs are utilized in numerous industrial and non-industrial applications.

Should You Use RTLS for Pallet Tracking? Probably Not

Typically, when discussing RTLS, one refers to mobile assets, including forklifts, vehicles, personnel, robots, AGVs, and drones. Much less about palettes.

Palettes are semi-mobile. Yes, they are moved, but they don’t move. Palettes are on the borderline between RTLS and RFID, or other identification methods, such as QR/bar code identification assisted by mobile robots, drones, or personnel.

One of the significant problems in warehousing is misplaced palettes. But employing RTLS for that is a bit of an overshoot because:

- Mobile beacons are expensive because they require a battery, electronics, and other components. Typically, tens of USD/EUR or more per mobile beacon (tag). To track forklift – fine. To increase the safety of people, it is okay. But to put it on thousands of palettes – too expensive, and still doesn’t solve many problems

- RFIDs are better, but as discussed, they don’t provide location information. They report, “I am close to the reader.” One needs to know the location of the reader to see the location of the palette

- RFIDs are far less expensive than mobile beacons for RTLS. But the reader must be mobile

- A mobile reader can take various forms, including a person with an RFID reader and a robot/drone equipped with a reader. It can be a static RFID scanner embedded in gates. The RFID reads out when the palette or the object with the RFID passes through the gate

- The same is valid for QR/bar code readers

RTLS Use Cases by Industry

- Forklift tracking for productivity

- Forklifts and vehicles tracking and geo-fencing against people and other vehicles for safety

- Forklifts and vehicles tracking and geo-fencing against AGVs

- Assets/palette tracking

- People tracking for productivity

- Geo-fencing zones in broader terms for safety

In general, usage in manufacturing is quite similar to warehousing and intra-logistics, as they share many of the same tasks and applications. Manufacturing has more variety:

- People tracking

- Vehicles tracking

- Geo-fencing zones for safety

- Cranes/hooks/load tracking against vehicles, people, AGVs

- Crane tracking in order not to violate the borders of the construction area

- Hooks against vehicles and people

- Cranes against drones

- People against dangerous zones – all sorts of geo-fencing zones

- Vehicle tracking and geo-fencing against people. Safety

- Vehicle tracking and geo-fencing against AGVs. Collision avoidance

- AGVs tracking and geo-fencing against people. Safety

- Autonomous robots

- Autonomous drones

- Autonomous vehicles

- People tracking for productivity

- Automatic task assignments for gauge readings or maintenance work based on people’s location

- More limitations due to explosion protection requirements => more expensive, heavier, bulkier, lower other performances

How to Choose an RTLS — Accuracy, Latency, Cost, and Range Compared

The answer to the question of what real-time locating systems are sound will depend on what you are looking for: accuracy, low latency, price, range, ease of deployment, ease of operation

- ±2cm: Marvelmind Indoor “GPS” – ultrasound-based RTLS

- ±10..30cm: UWB

- 1-2m: BLE with AoA

2-5m: BLE - Gate-level: RFID

- 100-400Hz and 5-10ms latency: IMU+Ultrasound or IMU+UWB sensor fusion

- 4-50Hz and 20-100ms: Marvelmind Indoor “GPS”, UWB, BLE – depending on the settings and mode

- RFID – not such a thing as a location update. RFID is not a real RTLS

The price of the system, the price of the mobile beacon (tag), the price of the stationary beacons and supporting infrastructure, installation costs, and maintenance costs – all these factors contribute to the overall cost. Ultimately, it depends on the exact configuration, requirements, specs, etc.

- ~1 cent: QR/bar code – Cranes tracking in order not to violate the borders of the construction area

- ~0.1 USD: RFID tag

- ~10-30 USD: BLE tag

- ~50-200 USD: UWB, ultrasound tags. Ultrasound stationary beacons. Active RFID tags

- 100-1000 USD: UWB anchors; specially protected tags (IP69, EX-protected, etc.)

- Global: GPS/GNSS

- 10-1000km: Cellular networks

- 10-50km: RTK GPS

- 100-500m: Marvelmind Indoor “GPS” with multiple submaps, UWB, BLE

- Up to 50m per submap: Marvelmind Indoor “GPS”, UWB

- Up to 10-30m per submap: BLE

What Are RTLS Tags? Mobile Beacons Explained

RTLS tags or RTLS mobile beacons are wireless devices placed on mobile objects to track their location inside the coverage area of RTLS (for example, building, warehouse, factory, hospital, etc.). You don’t track a person – you track their RTLS tag/mobile beacon. You don’t track a forklift – you track its RTLS tag.

RTLS Tags vs RFID Tags — Key Differences

An RFID tag can be considered an RTLS tag, but a very primitive and rudimentary one. Typically, RTLS systems provide 2D (XY) or 3D (XYZ) coordinates of the RTLS tags. At the same time, the RFID tags provide gate-level coordinates only. An RFID system doesn’t offer real-time coordinates of an RFID tag until the tag is placed on an RFID reader or passes through an RFID portal. Therefore, calling the RFID system a real-time locating system is a big stretch.

RTLS Technology Comparison — Ultrasound, UWB, BLE, RFID

Study more about different types of RTLS and RTLS technologies:

- Indoor navigation & positioning (PDF) – review and comparison of industrial indoor positioning technologies and methods

- Indoor navigation & positioning (YouTube video) – video based on the PDF above with additional insights